Stainless Steel or Aluminum? Material Considerations for Sterilization Cases & Trays

Surgical instrumentation used by medical practitioners must be cleaned and sterilized prior to use to mitigate the risk of patient infection and related complications. Sterilization cases and trays provide containment for the surgical instruments necessary to perform a procedure and facilitate both cleaning and sterilization. These containers also provide a means to ergonomically organize the instruments according to procedure cadence and offer protection during instrument transport.

The primary metals used to manufacture sterilization cases and trays are stainless steel and aluminum (specifically grades 304 stainless steel and 5052 aluminum). Each material can offer different advantages during and after production. Depending on your product and sterilization requirements, intended market location, and design considerations, stainless steel or aluminum may be a better option for your project.

Product Requirements

When considering which material to select for your sterilization container, think about your product requirements including instrument size, strength, durability, and weight.

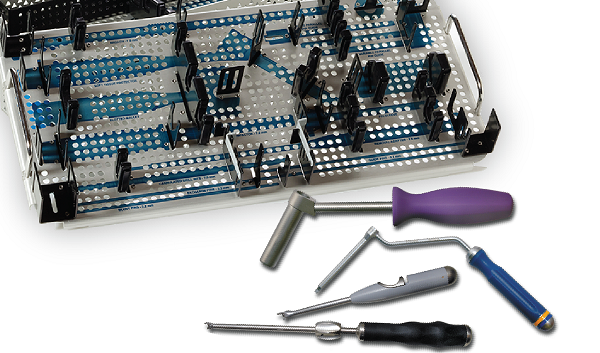

The size and mass of the surgical instruments can influence the choice of material used for the sterilization container. Large, heavy surgical instruments require a strong sterilization case. Orthopaedic large joint (hip and knee) replacement systems tend to contain large instruments with considerable mass. Small joint (upper extremity and spine), as well as ancillary devices, typically consist of smaller instruments with less mass. Stainless steel is stronger than aluminum, but aluminum has a much better strength to weight ratio comparatively. So, large/heavy instrumentation systems may perform better using stainless bracketry and smaller/lighter instruments may be better suited for aluminum.

The overall weight of an instrument system impacts both ergonomics and ability to sterilize. The Association for the Advancement of Medical Instrumentation (AAMI), an organization that develops and publishes standards detailing the proper production quality for medical instruments and procedures, recommends the weight of a sterilization container not exceed 25 pounds. This guideline ensures the containers are comfortable to handle and able to be sterilized properly.

When making material selections, you must carefully consider durability requirements, physical characteristics of the instruments to be contained, and the overall weight of the case and tray system.

Cleaning and Sterilization Methods

Sterilization cases and trays need to withstand the vigorous cleaning and sterilization processes required by the medical device industry. Cleaning typically consists of using water, and detergents or enzymatic cleaners, to reduce the bioburden and remove foreign material. After decontamination, surgical instruments are sterilized using processes validated by the manufacturer. These sterilization processes can be autoclaving (steam), ethylene oxide (EO) gas, hydrogen peroxide, radiation, and/or chemical solutions.

Depending on the geometry of the instrument, and the cleaning and sterilization processes required, some materials may be better suited for your project. Careful consideration should be made regarding the corrosive effects of the chemicals that come into contact with the sterilization container. Proper passivation of stainless steel or the anodizing/sealing of aluminum must be done to mitigate the degradative effects of these chemicals and processes.

It is also important to understand the regulations of the geographic location or country in which the product will be marketed. Certain regions of the world may have instituted sterilization regulations and/or have a preference about which sterilization method should be used.

Cost and Aesthetics

Although there have been recent fluctuations in the raw material markets due to supply chain issues, generally, stainless steels are more expensive than aluminum alloys. However, aluminum requires an anodizing and sealing process which creates an oxidized barrier to resist corrosion and wear.

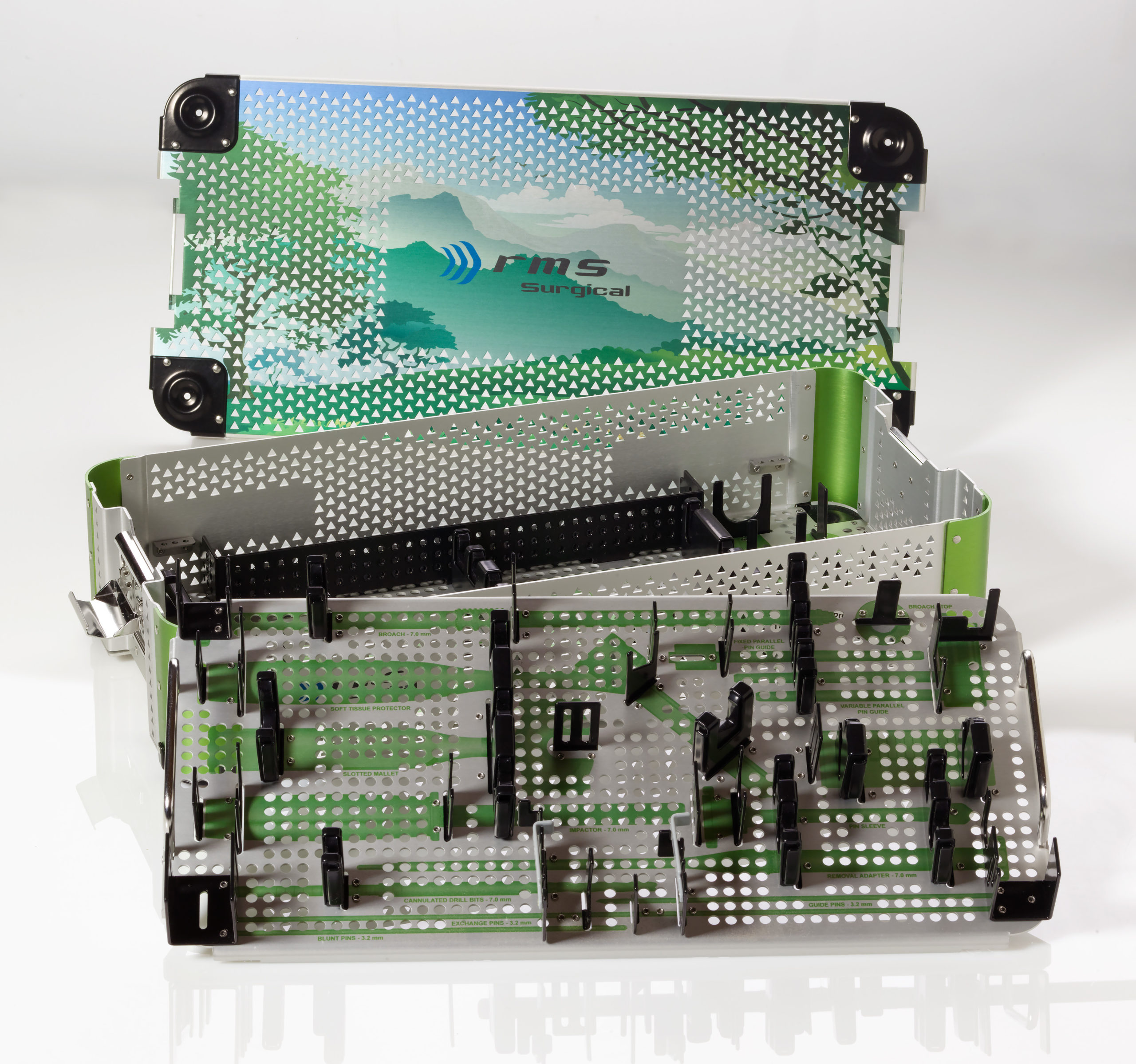

Anodizing adds additional cost but allows different colors and graphics to be achieved. For example, you can color-code surgical instruments for easy recognition and facilitate a more ergonomic surgical flow. You can also create visually attractive graphics and logos which aid in brand recognition and marketing activities. Stainless steel requires a nitric or citric passivation process which allows the choice of a brushed or polished finish but cannot alter the aesthetic appearance of the material, including color and graphics.

When considering which material to choose for your sterilization container, think about design and aesthetic considerations in addition to functionality requirements.

Stainless steel and aluminum have different properties and offer different advantages. When beginning the design processes for your sterilization case and tray project, consider durability, strength, and functionality requirements. You must also consider the preferred sterilization method of your intended market, associated costs, and design considerations such as color, graphics and surface finish.

rms Surgical can partner with you to choose the right material for your sterilization case and tray system. From hybrid designs to single or multilevel stackable cases and trays to caddies or nests, we have the expertise to help you optimize the design and production of your product.