Precision Tooling

In-House Tooling Capabilities

To best serve our customers throughout NPI, Transfer and Production projects, Cretex Medical has developed the expertise to fabricate the custom molds, dies and tools needed to manufacture your products and components to exacting standards. Our advanced teams exclusively support your internal tooling requirements. We are equipped with the skills and highly specialized technologies necessary to design, fabricate and maintain the complex tools we use to produce your devices and components.

Our state-of-the-art, in-house tooling proficiency includes the ability to design, build and optimize:

- Injection Molds (including multi-shot and insert molds)

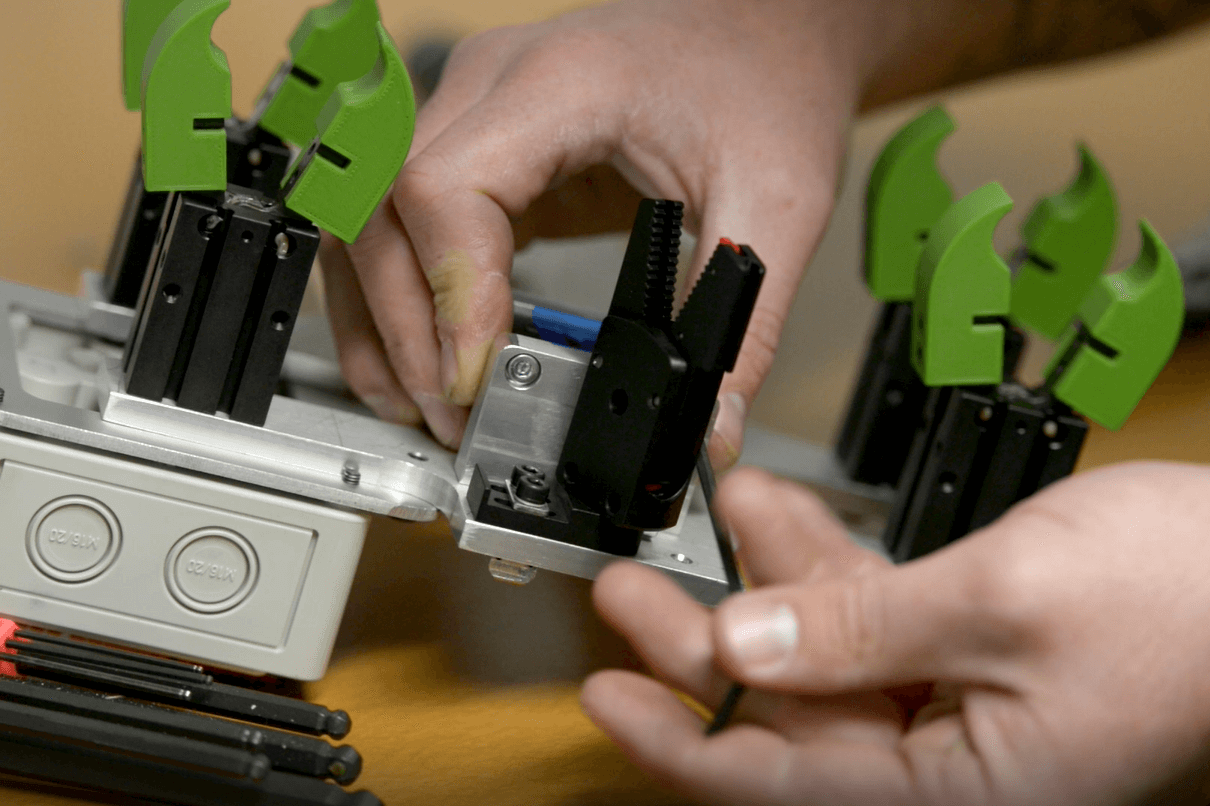

- Manufacturing and Assembly Fixtures

- Stamping Dies (progressive, transfer, single station and modular tooling)

- Custom Cutting, Profile and Surface Tools

- Custom Part-specific Inspection Fixtures

Tool Maintenance

Molds and dies are maintained at our in-house tooling shops to reduce down-time and assure they continue to meet the same exacting tolerances established during validation, even after years of production. Through our experience we have mastered intense quality control, high-, mid- and low-volume applications, and material research crucial for your successful project outcome.

Our Businesses

Surgical Instruments and Sterilization Cases & Trays

rms Surgical is a single-source provider of metal fabrication and precision machining services specializing in custom instrumentation and sterilization delivery systems.

Precision Machining & Additive Manufacturing of Implants & Components

rms Company provides contract manufacturing of high-quality, tight-tolerance medical implants, components and sub-assemblies using cutting-edge technology.

Molding, Design and Assembly

JunoPacific provides medical device molding and contract manufacturing services, specializing in micro-and multi-shot injection and high precision insert molding.