Machining

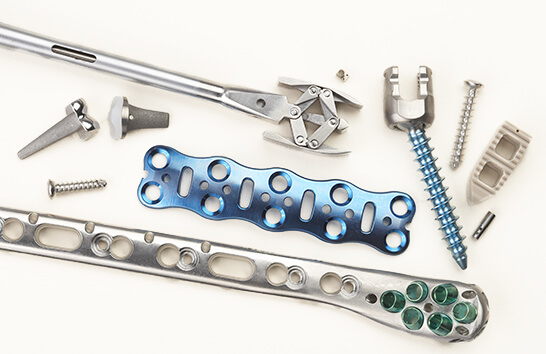

Medical Implants and Components

With more than 650 state-of-the-art CNC machine tools under one roof, rms Company produces high-quality, tight-tolerance implants, components and sub-assemblies.

For more than 50 years rms has built a reputation for being a highly responsive, technologically advanced source for machined medical device components and implants, supporting prototypes through major product launches. We constantly evaluate and incorporate the best technologies available to remain at the forefront of medical machining, which means you get the best quality and most efficient production.

Precision Machining Capabilities:

- Milling (up to 5-axis)

- Swiss and Conventional Turning (up to 13-axis with live tooling)

- Wire and Sinker EDM

- Ultrafast Femtosecond Laser Micro Drilling

- Direct Metal Printing

- Robotic Automation

Surgical Instrumentation

rms Surgical’s large inventory of vertical machining centers and multi-axis lathes give us the flexibility and capacity to create your custom surgical instruments. With over 100 state-of-the-art machining centers, we can create complex shapes in a single set-up. This reduces your production costs, time and risk.

Precision Machining Capabilities:

- Milling (up to 5-axis)

- Swiss and Conventional Turning (up to 13-axis with live tooling)

- Wire and Ram EDM (up to 5-axis)

- 5-axis Grinding

- Gun Drilling

- Robotic Automation

Our Businesses

Precision Machining & Additive Manufacturing of Implants & Components

rms Company provides contract manufacturing of high-quality, tight-tolerance medical implants, components and sub-assemblies using cutting-edge technology.

Surgical Instruments and Sterilization Cases & Trays

rms Surgical is a single-source provider of metal fabrication and precision machining services specializing in custom instrumentation and sterilization delivery systems.