Solutions

Powerful and scalable solutions for your medical device needs.

Project Management That's Dedicated to Your Success

You focus on innovation, let us focus on the details

At rms you will receive end-to-end project management support. With transparent communication, robust process validation, and expert supply chain management, rms can mitigate risks and control costs while driving on-time and on-budget delivery.

Our experts work closely with you to understand your timelines and customer needs.

Customer-Focused Project Team

With rms, we will shepherd your product from quote through validation into high production. Our process includes regular meetings and updates to drive quality, innovation and efficient problem solving. We will ensure cross-functional alignment while mitigating risks and managing changes. With proactive communication and clear escalation paths, our team will keep scope, timeline, and costs on track while protecting your critical-to-quality requirements.

Close collaboration drives creative solutions and speeds your product to market.

Process Validations

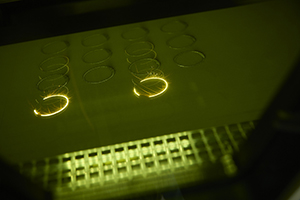

With a wide range of capabilities and decades of experience, rms will manage validations to make them as efficient as possible. We validate all aspects of our manufacturing processes, procedures and equipment to ensure adherence to your requirements and alignment with medical device industry standards. The result is a complete validation package with traceability, objective evidence, sustainable processes, and repeatable results.

Review a list of our validation activities.

Our robust validation program ensures your patients receive a high-quality product every time.

Managing the Supply Chain

Because we specialize in medical devices and components, we’ve built an extensive network of trusted suppliers with the capability and know-how to meet our rigorous standards in a timely manner. Supply chain continuity is critical to your success. We’ll work with you to design a sourcing plan that mitigates risk with consistency and reliability. With rms, you can have confidence in your long term plans and projections.

We work closely with suppliers to minimize the risk of any supply chain disruptions.

Drive Speed, Safety, and Savings Through DFM

Design for Manufacturability makes the production process more efficient from the start

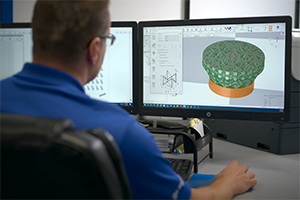

The best time to cut costs is during the design phase. Our Design for Manufacturability (DFM) process facilitates collaboration between your designers and rms experts. The rms team of manufacturing and quality engineering experts bring years of experience creating processes that drive efficiencies, while identifying opportunities for improving safety and quality.

Together, we’ll complete a detailed review of the part use, design requirements and tolerances. This exchange ensures that your products can be manufactured to achieve the required performance in the most economical way.

DFM Tools:

- CAD/CAM: ProEngineer, ProManufacturing, Solid Works and Unigraphics

- Systems and capabilities to validate FDA Class III manufacturing process

Process Development and Analysis

To ensure that the processes developed are robust and repeatable, we partner with customers to define and mitigate risks up front so they don’t slow down the product lifecycle.

This support extends beyond the manufacturing release so that the lessons learned are applied to further improve the process, quality and cost.

Our teams have decades of experience designing processes that eliminate waste and drive greater throughput.

Process Verification and Validation

Validation of the manufacturing processes is fundamental to ensuring that the best possible outcomes are achieved every time. When it comes to product quality and patient outcomes there can be no compromise.

We perform a wide array of validation activities.

At rms, our pride comes from delivering high quality products that ensure the health and safety of patients.

Scaling to Production

Speed. It is the name of the game in contract manufacturing. Once you have design and prototype approvals, you need product. We get it. That is why we continue to drive for shorter lead-times. We challenge ourselves and our suppliers daily, to eliminate every minute possible, so your customers can receive your products that much faster.

You can’t have speed without flexibility. That is why being part of the Cretex Medical family is so important. When you have a critical launch deadline to meet, we have the capacity and capital investment strength to meet or exceed your needs.

Through vertical integration, you have the full power of Cretex Medical available to support your launch.

Prototyping the Future of Medical Device Technology

Supporting you at every step from idea to high volume production

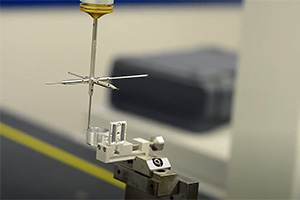

With the accelerating pace of medical technology advancements, it’s critical to get your idea to market before your competitors. Rapid prototyping is the key to making your design a reality. With our advanced technology, expert engineers and operators, and on-site tool room, rms can quickly create a prototype for your product so we can take it to the next level.

At rms, we also shorten lead times by embedding prototyping on the production floor. We use the same resources, tooling and processes to create your critical prototypes as we use for production released products. This ensures that the best manufacturing technology and talent not only creates your prototype, but is ready to launch your product to high volumes and meet your customers’ demand. There’s no time wasted transferring equipment or knowledge from prototype developers to production, because it’s all the same team.

On-site tooling allows us to iterate design and processes with speed, responsiveness and flexibility.

Operational Excellence at Our Core

Committed to getting better every day

Customer centricity is fundamental to the character of rms and Cretex Companies. That’s why Operational Excellence (OE) is not just a slogan or a project, it’s woven into everything we do.

At rms we’re proud of the industry recognition our OE program and use of lean management has earned. Not only do we focus significant resources and skills during the DFM stage, we also challenge our machinists and programmers to look for additional methods to improve your products’ throughput.

We look for process improvements wherever we can, from adding new machine tool technology to produce parts more efficiently, reprogramming CNCs to cut cycle times, or creating new fixtures and processes to generate less scrap. By obsessively finding and eliminating waste, Operational Excellence at rms is constantly creating more value for our customers.

Our continuous improvement processes and tools include:

- Visual metrics, standard work and daily tier meetings

- Value stream mapping

- 5S workplace organization

- A3 reporting

- Kaizen blitzes

- Employee-driven waste reduction and recognition

- Gemba walks

- Company-wide lean goals and project initiatives

- Lean practitioner and leadership training

Validation Activities

Our robust validation processes include, but are not limited to:

- Advanced Product Quality Planning (APQP)

- Installation Qualification (IQ)

- Operational Qualification (OQ)

- Performance Qualification (PQ)

- Production Part Approval Process (PPAP)

- Process Failure Mode and Effects Analysis (PFMEA)

- Gage Repeatability and Reproducibility (GR&R)

- Cleaning Validations

- Capability Analysis

- Validation Protocol Development

- Statistical Support for Validation Planning and Execution

- Assessment and Leveraging of Product Families