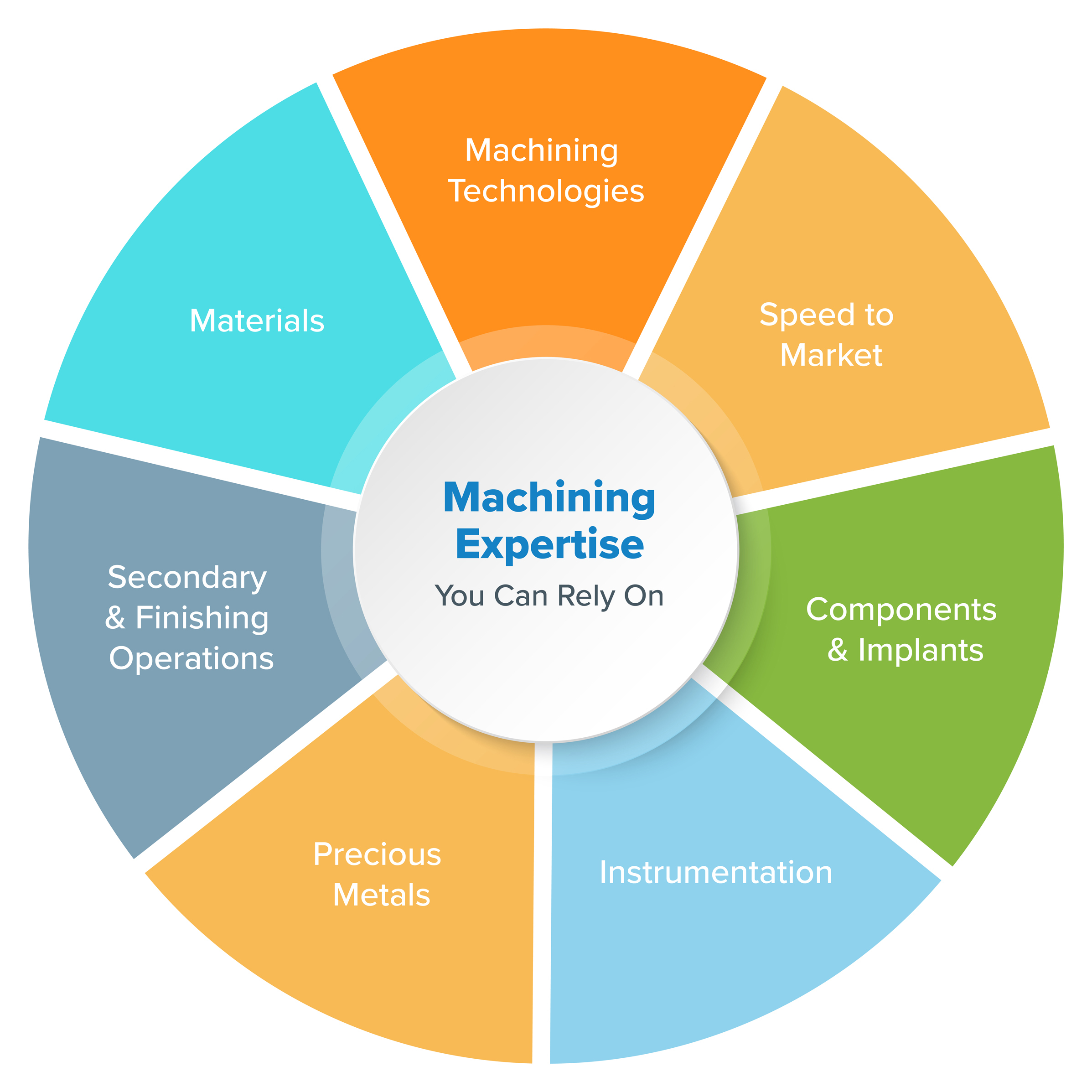

Machining

Advanced Machining Solutions

Put the power of rms technology and experience to work for you and your products

With over 900 high-precision machine tools in a range of platforms, we have both the expansive capacity and high-tech capability to meet your machining needs. We constantly evaluate our tools and processes to ensure we employ the advanced technologies and most efficient techniques to provide the best value to you.

Technology & Equipment

- Milling centers up to 5-axis

- Mill turning centers up to 8-axis

- Swiss turning centers up to 13-axis

- Conventional CNC lathes up to 13-axis

- Grinding up to 5-axis

- Wire and Ram EDM up to 5-axis

- Sinker EDM

- Gun Drilling

- Robotic Automation

Our expertise extends to many markets, including:

- Cardiac Rhythm Management and Pacing

- Orthopaedic and Sports Medicine

- Neuromodulation

- Interventional

- Drug Delivery

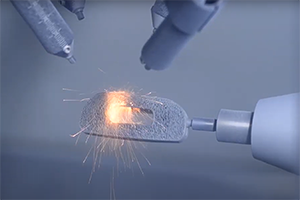

Ultrafast Laser Micro Machining

Our femtosecond laser platforms support advanced machining operations well beyond the capability of conventional drilling technology. We excel at small features, drilling holes as small as one thousandth of an inch in diameter. Holes can be cylindrical, elliptical, positive or negative taper.

To avoid the problem of overheating materials (which would require time-consuming secondary processing), the rms platform uses an ultrafast pulse. That essentially creates a fast and efficient athermal process to avoid material damage.

Laser Features

- 5-axis motion control and 5-axis laser control

- Straight, tapered, and reverse tapered holes down to Ø.001”

- 7:1 Feature aspect ratio

- True athermal ablation with no heat affected zone

- Positional accuracy: ±.00004” (1 Micron)

- Typical diameter tolerances: ±.0004” or less

- Surface quality of inner wall: Ra < 0.1 Micron

- Maximum stock size: 8.25”x4.7”x5.9” (3 Axis) or Ø2.9”x5.9” (5-axis)

Accelerating production with advanced technology, like the femtosecond laser, saves customers time and money.

Typical Tolerances and Capabilities

The following represent the typical tolerance guidelines but as we continue to push the boundaries through new technologies these do not necessarily represent the final limits of capability.

| Machine Type | Material Stock |

| High-speed 5-axis mills | 0.010″ (0.25 mm) to 18.0″ (460 mm), cylinder or square |

| 13-axis Swiss | 0.060” (1.52 mm) to 1.5” (38 mm), cylinder or square |

| Lathe turning | 0.05” (1.27 mm) to 4.0” (100 mm) |

| 5-axis wire EDM | 0.025″ (.635 mm) to 14.0″ x 8.0″ x 9.0″ (355.0 X 203.2 X 228.6 mm) |

| 4-axis RAM EDM | |

| Femto second laser | |

| *Fine cut Nd:YAG laser | |

| Laser welders | titanium, platinum, stainless steel |

*0.002″ (0.05 mm) Diameter Beam

| Features | Typical Limits | Extreme Limits |

| Diameter | +/- 0.0005″ | +/- 0.0001″ |

| Length | +/- 0.001″ | +/- 0.0005″ |

| Profile | 0.002″ | 0.001″ |

| Position | 0.002″ | 0.001″ |

| Surface finish | 16 Ra | 4 Ra |

| Sharp corners | 0.003″ | 0.001″ |

| Wall thickness | 0.005″ | 0.002″ |

| Pocket milling depth | 3x to 6x diameter | 7x to 10x diameter |

| Inside fillets | 0.005″ | 0.002″ |

Accelerating Your Products to Market

Streamlining every stage, from concept to full-scale production

Making it easier to get your products to patients is at the heart of what we do. At rms, our team has deep expertise in machining for a wide range of medical device categories. Our proven processes, rigorous quality standards, and track record of innovation mean that we can scale with you as you grow.

From early development to full-scale production, our experts provide the technical insight and reliable execution needed to accelerate timelines and reduce risk. Whether it’s delivering precision components for cardiac devices, complex implants for trauma procedures, or durable instruments for joint replacement, we help our customers meet the highest expectations for performance and safety.

With Design-for-Manufacturing, advanced and automated technology, and an Operational Excellence mindset, we will find efficiencies that help control costs while scaling up volumes to meet your goals.

Precision-Machined Components & Implants

High-tech solutions from head to toe

Whatever area of the body your device is designed for, rms has the manufacturing capabilities and production acumen to deliver high-quality, tight-tolerance components and sub-assemblies that help the human body perform as naturally as possible.

Driving Efficiency and Value

With rms you will have an ongoing partner dedicated to managing costs and delivering with high quality. We will work with you to implement Design for Manufacturability (DFM) whenever possible to ensure function while simplifying production processes. Our culture of continuous improvement guarantees that we will always be looking for ways to manufacture your products smarter and faster.

We supply precision machined components and implants for a wide spectrum of medical devices across multiple markets, including:

Orthopaedic, Spine and Sports Medicine

- Artificial discs

- Spinal fixation systems

- Interbody fusion devices

- Vertebral body replacements and spacers

- Internal fixation plates and screws

- Artificial joints

- Soft tissue reattachment devices

Cardiac Rhythm Management

- Electrodes

- Pin connectors

- Crimp sleeves

- Feedthroughs and flanges

- Header components and connector blocks

- Markers and marker bands

- Cases, cans and housings

- Welded assemblies

- Set screws

Other Markets

- Drive shafts

- Drug pump housings

- Ablation catheter components (thermal and cryogenic)

- Endoscopy

- Urology

Instrumentation for Multiple Markets

Decades of experience manufacturing surgical instruments, tools and accessories

Our large inventory of vertical machining centers and multi-axis lathes give us the flexibility and capacity to meet your needs. With state-of-the-art machining centers we can create complex shapes in a single set-up, reducing your production costs, time and risk.

- Single-use instruments

- Multi-use instruments

- Orthopaedic instruments

- Temporary or trial implants

- Tunneling and delivery tools

- Powered surgical housings and components

- Rasps and broaches

- Reamers and cutting tools

- Drills and drill guides

Precious Metal Specialization

Dedicated resources and proven results for high-tech components

For advanced devices that rely on the unique properties of precious metals (biocompatibility, corrosion resistance, strength, etc.), rms has the expertise and resources to support your needs. Our specialized manufacturing techniques ensure tight tolerances and repeatable results. We can also help you select the right alloy for your device, including platinum, iridium, palladium, tantalum, or nitinol.

With our dedicated precious metals team, we have the resources and know-how to deliver high-quality components consistently and at scale, from fine wire and electrodes to complex assemblies.

Our dedicated platinum operation includes 54 Swiss turning and 16 wire EDM machines.

Complete Production Support Through Secondary Operations

Simplifying the supply chain through vertical integration

rms Company has a complete array of secondary and finishing operations, including on-site and out-sourced capabilities. We can also leverage the expertise and capacity of the full Cretex Medical family of companies to shorten your supply chain.

Our wide variety of onsite secondary operations include:

- Tumbling

- Vibratory

- Centrifuge

- Disc

- Deburring

- Cryogenic

- Chemical

- Mechanical

- Blasting

- CNC blasting

- Micro-blasting

- Bead blasting

- Titanium nitride (TiN) coating

- Automated and manual polishing (including cobalt chrome)

- Fully automated passivation system

- Type I and II

- Cleaning

- Vapor and ultrasonic

- Color anodize – Type III

- Laser marking

Assembly Capabilities

Taking the process a step further, rms has the resources to convert components we machine into sub-assemblies and assemblies to further reduce your inventory requirements and assembly time.

- Laser welding and assembly

- Mechanical assembly

- Cleanroom assembly

We accelerate production and decision-making while ensuring the highest quality standards.

Outsourced Capabilities

To provide the widest range of available finishing options, rms has developed a network of approved and qualified outsource partners.

- Anodize – Type II

- Electropolishing

- Heat treatment

- Plating

- Castings

- TPS/plasma coating

- Shot peening

- Bending

Our suppliers have demonstrated the ability to meet the strict quality standards of medical device production.

Leverage the Power of Cretex Medical

In addition to our onsite capabilities and network of 3rd party suppliers, rms is part of Cretex Medical and is vertically integrated with Cretex Medical | CDT and Cretex Medical | QTS to deliver a complete solution.

Cretex Medical | CDT offers injection molding, progressive stamping, laser processing, and advanced assembly for medical device components and devices.

Cretex Medical | QTS offers cleaning and passivation, assembly, kitting, packaging, labeling, inspection validations, sterilization management, supply chain management, and pre-validated packaging and sterilization solutions.

Partner with rms for all the capabilities you need to develop, scale, and deliver your devices to patients.

Cretex Medical provides access to a variety of industry leading medical device and device component solutions, including:

- Injection Molding

- Progressive Stamping

- Laser Processing

- Finished Device Assembly

- Sterile Packaging

- Sterilization Management

- Pre-Validated Packaging and Sterilization Solutions

- Supply Chain Management

Materials

Expertise in a variety of medical-grade materials to meet your needs

Material choice is crucial in designing medical devices, influencing performance, biocompatibility, and longevity. Our applied understanding of material properties and machining characteristics allows us to select the right tooling, reducing variability, maintaining tolerances, extending tool life, and controlling costs. This practical knowledge also informs a robust Design for Manufacturability (DFM) process.

Metals

- Stainless steel

- 300 series

- 400 series

- 17-4

- Cobalt chrome

- Titanium

- Commercially pure grades: 1 – 4

- 6AL-4V and other alloys

- MP35N

- Platinum and platinum/iridium alloys

- Inconel

- Kovar

- Niobium

- Monel

- Nitinol

- Nickel

- Molybdenum

- Aluminum

Polymers

- PEEK

- Implantable grades

- Commercial grades

- UHMW polyethylene

- Radel

- Propylux

- Polysulfone

- Tecapro

- Ultem

- Polycarbonate

- Acetal copolymers

- Silicone