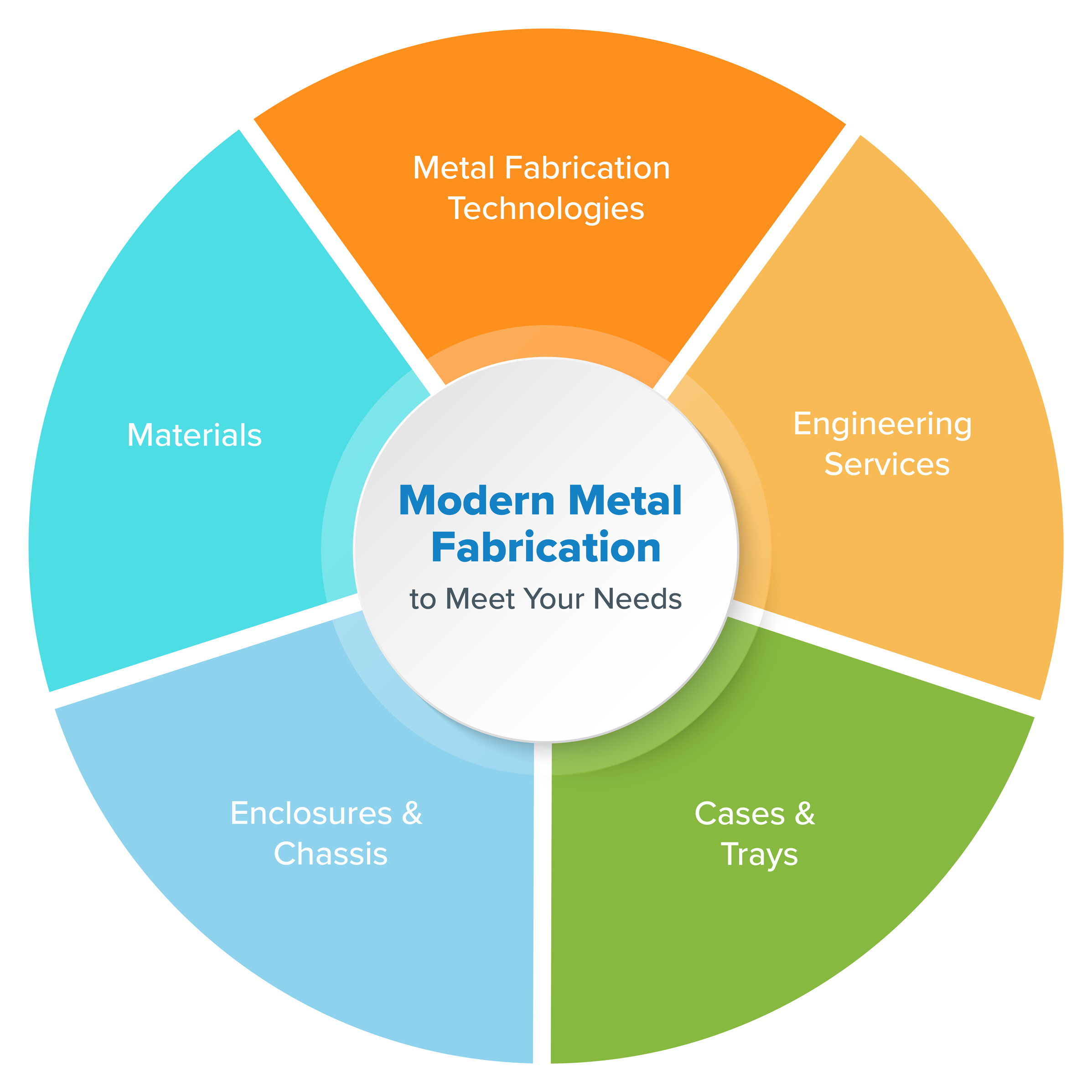

Metal Fabrication

Metal Fabrication Powered by Technology and Expertise

Driving efficiency while maintaining the highest quality standards

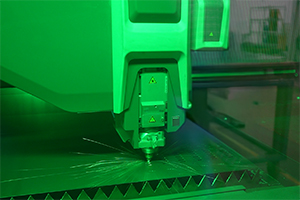

Our facilities leverage the newest technologies, from laser cutting to robotic automation. Enhancing precision, reducing human error, and maximizing efficiency ensures that we not only meet exacting standards, we can also deliver solutions that control costs and support your growth. Whatever level of output you need we can scale with you.

Metrology

Our sophisticated metrology expertise and technology distinguishes us in the field. It’s much more than a tape measure. Learn more about our commitment to regulatory compliance and quality assurance.

Manufacturing Capabilities

- Metal Fabrication using:

- Laser Cutting

- Stamping

- Turret punching

- Press Brake Forming

- CNC machining

- Wire Forming

- CNC Machining of metals and polymers:

- Turning (Conventional and Swiss)

- Milling

- EDM (Wire and Plunge)

Finishing and Secondary Operations

- Metal finishing

- Welding

- Tumbling

- Blasting

- Passivation

- Surface Treatment

- Passivation

- Electropolishing

- Anodization

- Nylon Coating

- Assembly

- Hardware insertion

- Marking

- Silk Screening

- Laser Marking

- Anodized Graphics

Advanced Technology

- Amada Laser/Turret combination with auto loading towers

- Safan Darley brake presses

- Bystronic ByCut Star with BTE automation and tower

- Auto-Sert / Haeger fastener insertion technology

- Trumpf laser marking

- Integrated automation

- Integrated robotic assist capability

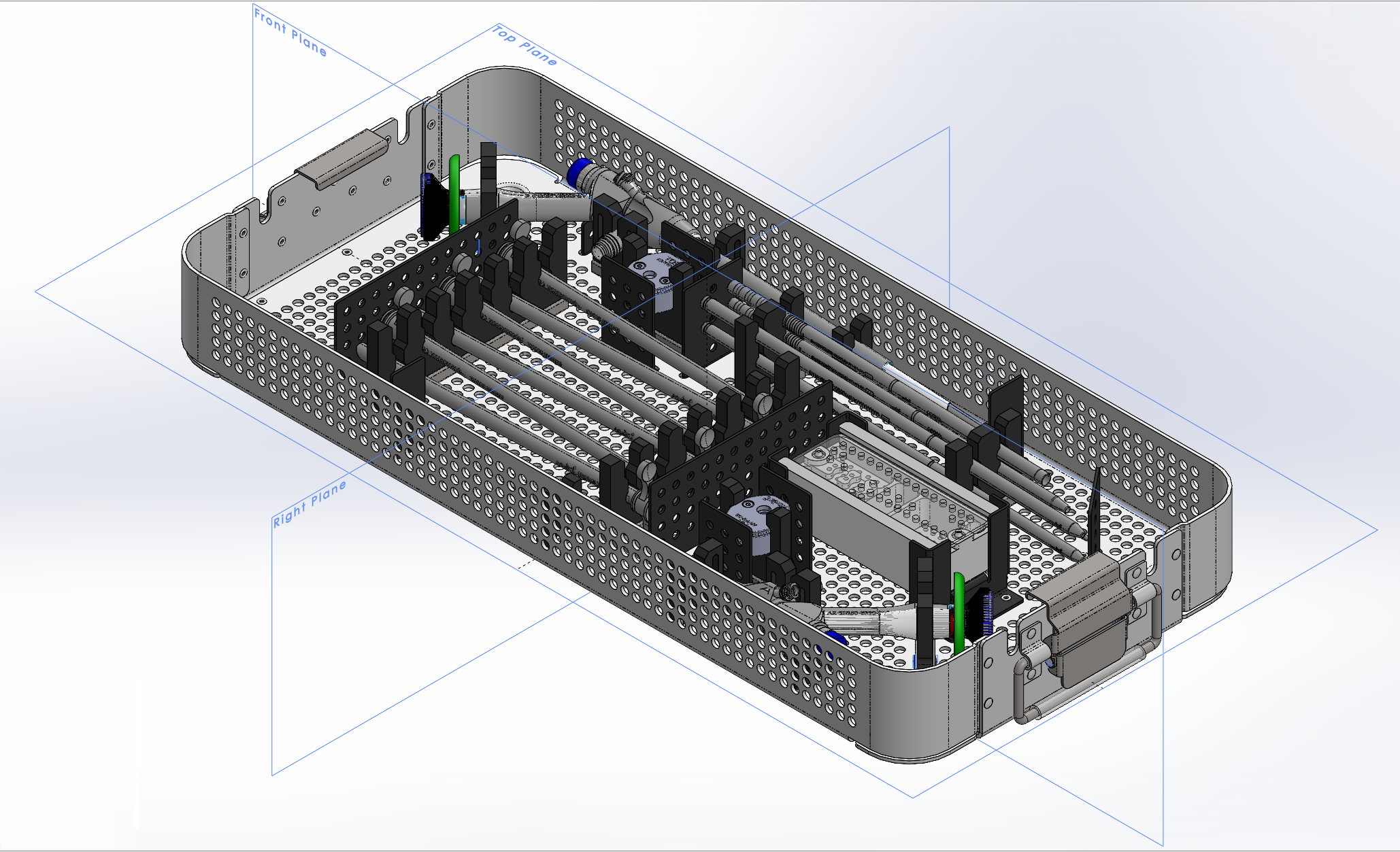

Collaborative Engineering to Bring Your Vision to Life

Optimizing design for efficiency and functionality

You need a partner with expertise in design for manufacturability (DFM) who can provide critical analysis to ensure optimal design strength and efficient manufacturing processes. We’ll create a manufacturing process that is as efficient as possible so we can pass those savings on to you.

Our expert team is always looking for ways to drive efficiency and improve quality.

Design and DFM

Our team of engineers can work with you directly on device design and graphics, or we can take your initial concept and run with it.

Designing a case, tray or enclosure requires answering every question. How do you increase the number of instruments in a tray without jeopardizing air flow for dry time? Do you have a unique user need or design input? Can you pass the drop test? Will the device enclosure be ergonomically user-friendly in the operating room? Our engineers will help you answer those questions while designing a process that maximizes efficiency to drive down costs.

We have the tools and track record to find creative solutions that improve the production process.

Support Services

Our dedicated support team has the breadth of knowledge and expertise to deliver the best customer experience possible. Throughout the launch process you’ll have an extra set of eyes on your project to keep it on time and on budget. From concept to production, we’ll have your back.

You will receive frequent and transparent communication from the project team to make sure you’re not hit with unwelcome surprises.

Prototyping

The best way to assure the fit and function of your product is to hold a live prototype in your hands. Our rapid prototyping approach allows us to turn your prototype in as little as a week’s time. With prototyping from rms you can meet your deadline confident in performance and quality.

Our wide range of onsite capabilities helps us deliver completed prototypes faster.

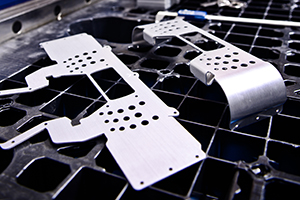

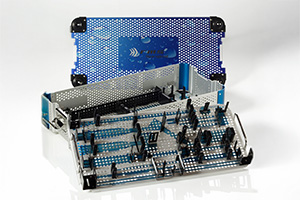

Cases & Trays for Any Surgical Setting

Advancing ease of use and sterilization efficiency

Our experts are dedicated to maximizing the number of instruments in each case while maintaining proper airflow and drying time, and they will work with you to reduce weight in your design without jeopardizing structural integrity.

Smart design not only maximizes the number of instruments a tray can hold, but arranges them to maximize convenience for the end user while minimizing cleaning and dry time. We can also design embedded graphics to improve aesthetics and usability.

Applications

- Single or multilevel-stackable cases and trays

- Caddies

- Aluminum and stainless steel construction

- Metal/polymer/silicone hybrid designs

- Embedding graphics with anodization, laser marking or silk-screening

Well-designed instrument trays ensure ease of sterilization and improve ergonomics in the operating room.

Medical-Grade Enclosures & Chassis

Specialized metal enclosures for your medical devices and equipment

We can design and manufacture enclosures that not only support the functionality of your medical device but maximize usability in the operating room. Optimizing design means finding ways to ensure durability and ease of cleaning while managing costs.

Capabilities

- Marking and Labeling

- Assembly

- Gasket assembly

- EMI shielding assembly

- Metals and polymers

Applications

- Capital equipment

- Patient monitoring

- Robotic surgery frames

- Ablation platforms

- Generator housings

- Peripheral equipment

Materials

Finding the right material for your market and needs

With decades of experience in stainless steel, aluminum, polymers and other materials, we can work with you in the design process to consider market requirements, sterilization needs, durability, strength, functionality, aesthetics and cost.

From hybrid designs to single or multilevel stackable cases and trays to caddies, whatever material you choose we have the expertise to help you optimize the design and production of your product.

Metals

- Stainless steel

- Aluminum

- Carbon steel

Polymers

- Radel®

- Propylux®

- Tecapro

- Silicone