3 Unexpected Benefits of Additive Manufacturing in Your Production Process

The additive team at rms Company uses Direct Metal Printing (DMP) to manufacture production-level quantities of medical device implants and components for our customers. However, we also use our in-house metal and polymer 3D printing capabilities in a variety of ways to drive efficiencies across all our manufacturing processes.

Additive manufacturing (AM) is a powerful, if underutilized, pre-, and post-production tool. Here are three ways you can utilize AM to benefit your manufacturing process.

TRAIN OPERATORS

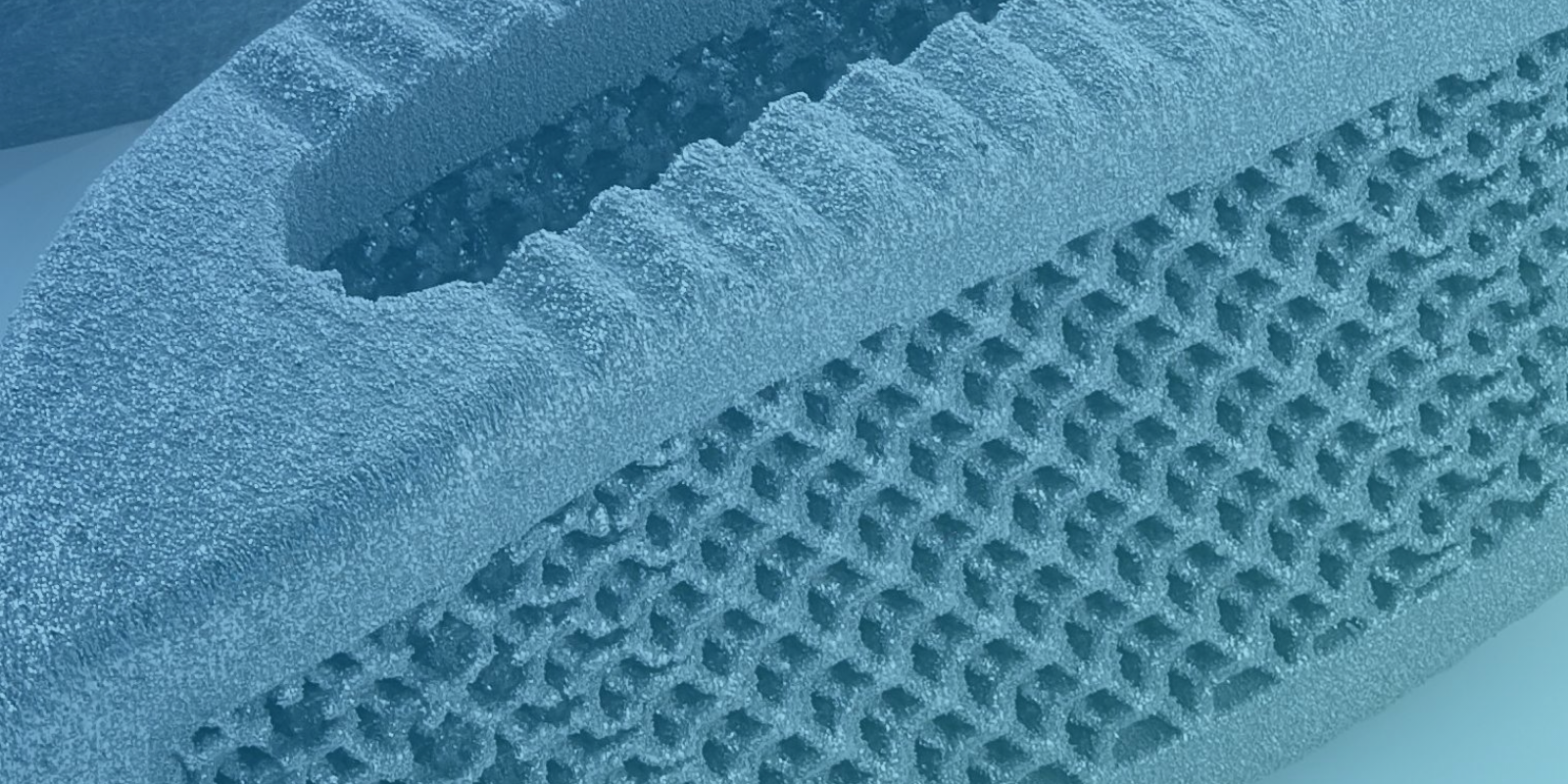

Additive manufacturing can be utilized to teach operators by distributing scaled versions of small parts during training. For example, the biopsy forceps jaw (left) was enlarged about 30 times for increased visibility.

Enlarging parts gives operators a chance to see and physically examine a part without the use of a microscope. This facilitates better understanding because rather than describing what to look for under a microscope, features can be shown clearly by pointing to them on the enlarged part. AM can even be incorporated into Process Failure Mode Effects Analysis (PFMEA) to find and correct potential errors and failures before production.

TEST DESIGN ITERATIONS

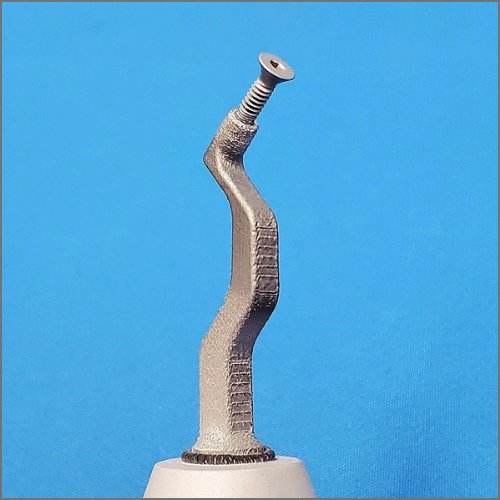

If you are looking to test design iterations quickly, you may want to investigate additive manufacturing. AM can produce design iterations and parts very quickly, sometimes in a matter of hours. The technology can save time during R&D and allows for better planning and testing.

In addition to producing test design iterations for plastic injection molds and tools, 3D printing can also test iterations for Operational Excellence (OE) initiatives such as ergonomic tools, part carriers, part presenters and organizers. Even if the final solution needs to be made of another material, like titanium, the first few iterations can be quickly and accurately created with polymer 3D printing.

FIND EFFICIENCIES

While additive manufacturing does not usually result in overall cost reduction, AM can be utilized to reduce fixturing costs and meet OE initiatives. By 3D printing fixtures for your inspection or assembly processes, you can save time and reduce cost compared to traditionally machined fixtures. Even if additive manufacturing is not the most effective method of production for your medical device or component, the speed and cost at which fixtures can be produced via 3D printing make AM a cost-effective option for fixturing.

3D printing can also be used to meet Operational Excellence initiatives, increase efficiency, and make the manufacturing process more comfortable for operators and assemblers. For example, QTS has used polymer 3D printing to make part organization trays with rounded corners. This prevents very small parts from getting stuck in the corners of the organizational tray and reduces physical labor during assembly.

With additive technology becoming more accessible, now is the time to think about incorporating AM into your manufacturing process. From pre-production as a training tool or means of testing design iterations, to meeting operational excellence initiatives post-production, additive manufacturing can increase efficiencies in your manufacturing process.